We came up with Alcheman after doing a lot of research into the 3D printing industry. We discovered that although high-performance specialty materials like PEEK, PC, PEI, PA, and PPS have a lot of potential for use in things like drones, sports, aerospace, cars, and medical devices, 3D printers on the market that can effectively handle these complex materials are mainly concentrated in expensive industrial-grade products, making it difficult for them to meet the needs of ordinary consumers.

Alcheman’s Mission

The name "Alcheman" comes from "alchemist," which represents the spirit of exploring the unknown and pursuing transformation and change. Just as alchemists turned ordinary substances into precious metals, Alcheman is dedicated to making high-end manufacturing technology accessible, helping everyone to create with ease, and expanding the boundaries and possibilities of creativity.

Alcheman's Core Value Proposition

In the maker community, lots of people use 3D printers to bring their ideas to life. But when they actually use them, they're often disappointed. The models aren't resistant to impact, are easily deformed, have poor usability, and end up being more like "artifacts." Alcheman is the bridge that turns ideas into reality. From aerospace and automotive parts to high-impact robots and drones, Alcheman can print models with high hardness, impact resistance, and deformation resistance. The result is work that's not only aesthetically pleasing but also built to last.

"Say Goodbye to Superficial Creations" At Alcheman, we're dedicated to helping creators go beyond the surface to build truly functional, long-lasting masterpieces.

Meeting Market Needs

We saw a big demand for high-performance material printing and knew we could do better than what was out there. So, we set out to develop a desktop 3D printer that could handle specialty consumables at an affordable price point. That's how Alcheman's first product came to be. It broke through the limitations of traditional high-performance material printing and expanded professional-grade creations from industrial to consumer-grade equipment, making high-end manufacturing technology accessible to everyone.

Challenge 1: Printing high-performance materials at high temperatures. Printing high-performance materials requires extremely high temperatures, and traditional printers often struggle to maintain these conditions. Here's the solution: The Alcheman has a patented high-temperature print head and a high-performance heat bed, so it can keep going in environments up to 480°C. The Alcheman is built to print on the toughest materials out there. It can print the most challenging materials on the market, such as PEEK, PEI, PC, PA, etc., with great industrial-grade results.

Challenge 2: The second challenge is making sure that all these high-performance materials work well together. When we were developing Alcheman, the biggest challenge for the team was figuring out how to make it work with all these different high-performance materials. Each specialty consumable, such as PEEK, PEI, PC, PA, etc., has its own melting point, cooling characteristics, and adhesion needs. Here's the solution: To make sure we got the best printing results with each material, the team spent 4,000 hours testing to find the best combination of printing settings to use in the slicing software. The software automatically applies these proven settings when the user selects a specific material, so you can print with stability and precision.

Challenge 3: Making it easy for users to use. Printing on high-performance materials often requires some pretty complex setups and adjustments. The team wanted Aclehman to be easy for users to use, regardless of their experience level. Here's the solution: The solution was to create an intuitive user interface and an automated calibration and configuration system that adjusts the print parameters based on the user-selected materials and provides real-time solution recommendations when problems arise. At the same time, the system has a built-in model library that makes it easy for the user to select and print the required models.

Application of High Performance Filaments

Alcheman makes it easy to print high-performance, durable materials like PEEK, PA, PEI, PC, and PPS. With active bin temperature control, environmental variable control algorithms, higher nozzle and hot bed temperatures, and multiple expert and user-tested parameters, Alcheman gets the best results in material fusion bonding and layer aggregation forces. This reduces the risk of failure due to warpage. The new Alcheman model is designed to keep print failures due to warpage to a minimum. Its powerful cooling system keeps the material at the right temperature for precise curing, which means higher speeds and more accurate detail reproduction.

Ultra-High Detail Reproduction

After two years of testing vibration compensation, hydrodynamics, and flow rate calibration algorithms, Alcheman can accurately calibrate X- and Y-axis resonance in real time. It can also actively compensate for material flow rates, ensuring that every detail of a print job is faithfully reproduced with 93% or more detail reproduction.

Automatic Calibration and Mesh Bed Compensation

As the hot bed heats up and the base plate deforms due to thermal expansion, Alcheman's fully automated micron-level calibration and levelling feature quickly scans the hot bed at high temperatures and makes adjustments for thermal expansion using its own algorithms, enabling fully automated zeroing of the print plane. The non-contact scanning and levelling means that the nozzles aren't subjected to any impacts that could shorten their life.

Reliable and Flexible Structure

The Alcheman has a metal frame and carbon fiber parts that are solid but not too heavy, so it prints fast and consistently. The sturdy frame and lightweight components mean you get better print accuracy, fewer failures and a longer life.

Triple Protection Against Microparticle Threats

Alcheman has triple high-efficiency micro-particle filtration for ABS and volatile consumables, so you can print safely and healthily.

Larger Print Size and Better Experience

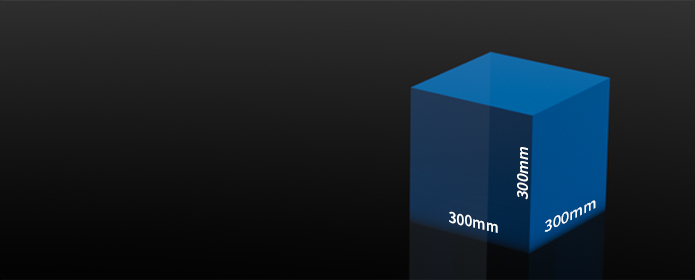

The 7-inch screen makes browsing a richer experience, and the 300*300*300mm print size gives you more room to play, so you can print larger models with ease.

Reliable and Flexible Structure

The Alcheman has a metal frame and carbon fiber parts that are solid but not too heavy, so it prints fast and consistently. The sturdy frame and lightweight components mean you get better print accuracy, fewer failures and a longer life.